The Ferrari DEIS II diagnostic tool was developed as part of Ferrari's commitment to maintaining the performance, safety, and reliability of its high-end vehicles. Here’s an overview of how DEIS II was invented and developed:

1. Evolution of Automotive Technology:

As automotive technology advanced, particularly in luxury and performance vehicles like Ferrari, the need for sophisticated diagnostic tools became apparent. Increasingly complex electronic systems, including engine management, safety features, and infotainment, required specialized tools to monitor and diagnose issues.

2. Identifying Diagnostic Needs:

Ferrari recognized that its authorized service centers needed a dedicated diagnostic solution tailored specifically for its vehicles. This was essential to ensure that technicians could efficiently diagnose and repair complex systems while adhering to Ferrari's high standards of performance and quality.

3. Development of Proprietary Software:

The development of DEIS II involved creating proprietary software that would interface with Ferrari's unique electronic control units (ECUs). This software was designed to provide in-depth diagnostics, including fault code reading, live data monitoring, and programming functions.

4. Collaboration with Engineers:

Ferrari’s engineering teams collaborated with diagnostic technology experts to design a tool that would meet the specific requirements of Ferrari vehicles. This collaboration ensured that DEIS II would not only be effective but also user-friendly for trained technicians.

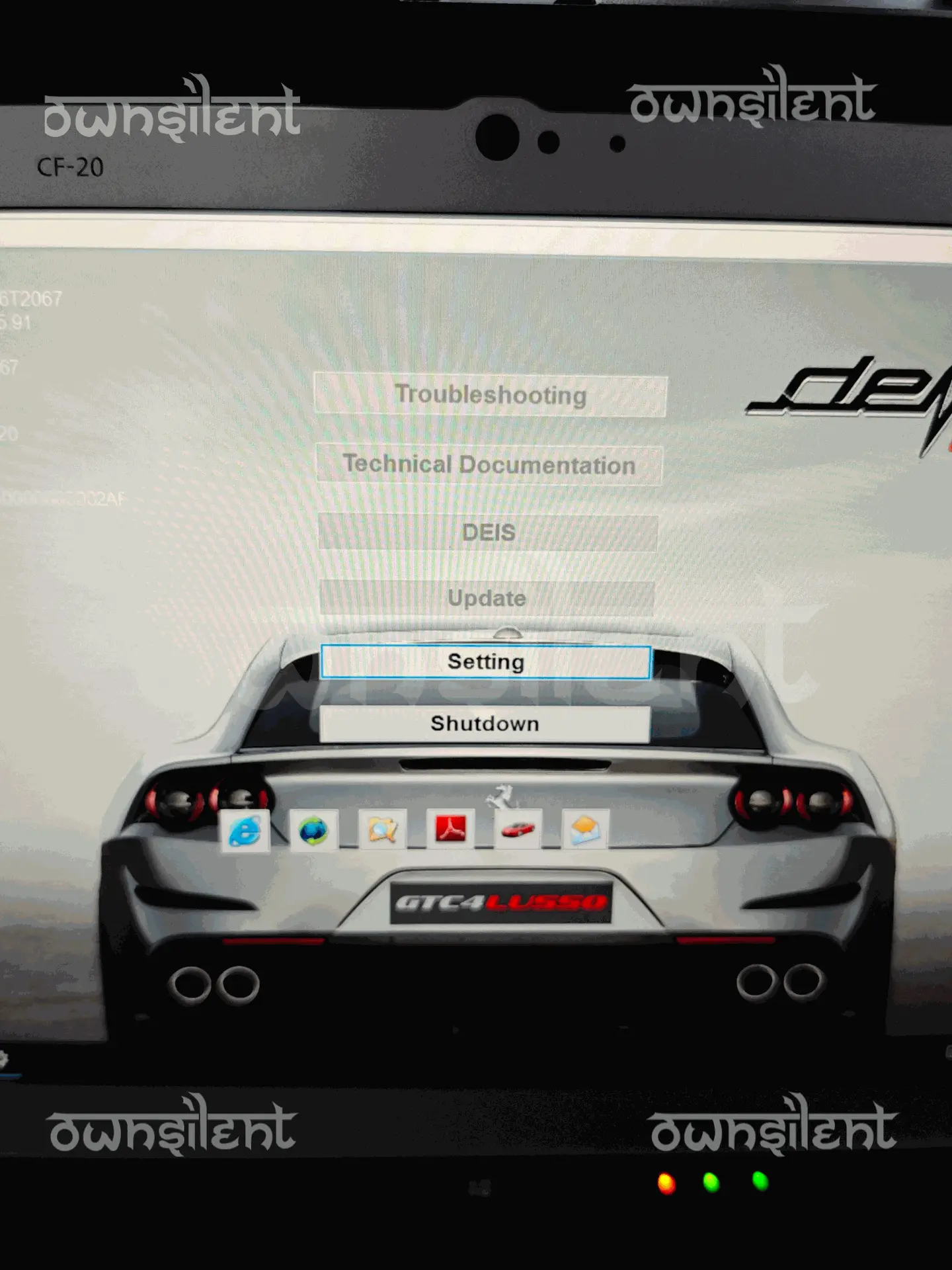

5. Integration with Rugged Hardware:

To enhance usability in workshop environments, DEIS II was paired with rugged hardware, such as the Panasonic Toughbook CF-19 or CF-20. This choice ensured that the tool could withstand the demanding conditions of automotive service while providing the necessary computing power for complex diagnostics.

6. Testing and Iteration:

Extensive testing was conducted to ensure the accuracy and reliability of the DEIS II system across various Ferrari models. Feedback from technicians using the tool in real-world scenarios helped refine the software and improve functionality.

7. Deployment in Service Centers:

Once fully developed and tested, DEIS II was deployed in authorized Ferrari service centers around the world. Training programs were established to ensure that technicians were proficient in using the tool effectively.

Conclusion:

The invention of the Ferrari DEIS II system was driven by the need for a specialized diagnostic tool that could handle the complexity of Ferrari vehicles. Through a combination of engineering expertise, rigorous testing, and a focus on user experience, DEIS II has become an essential tool for maintaining the performance and reliability that Ferrari is renowned for.